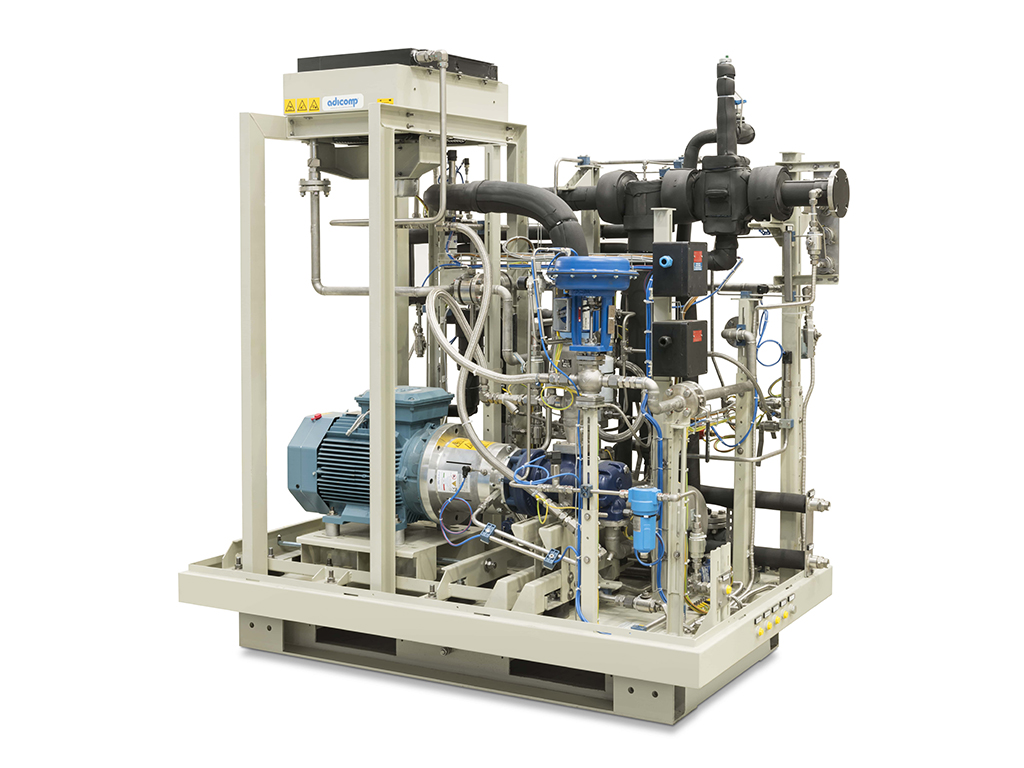

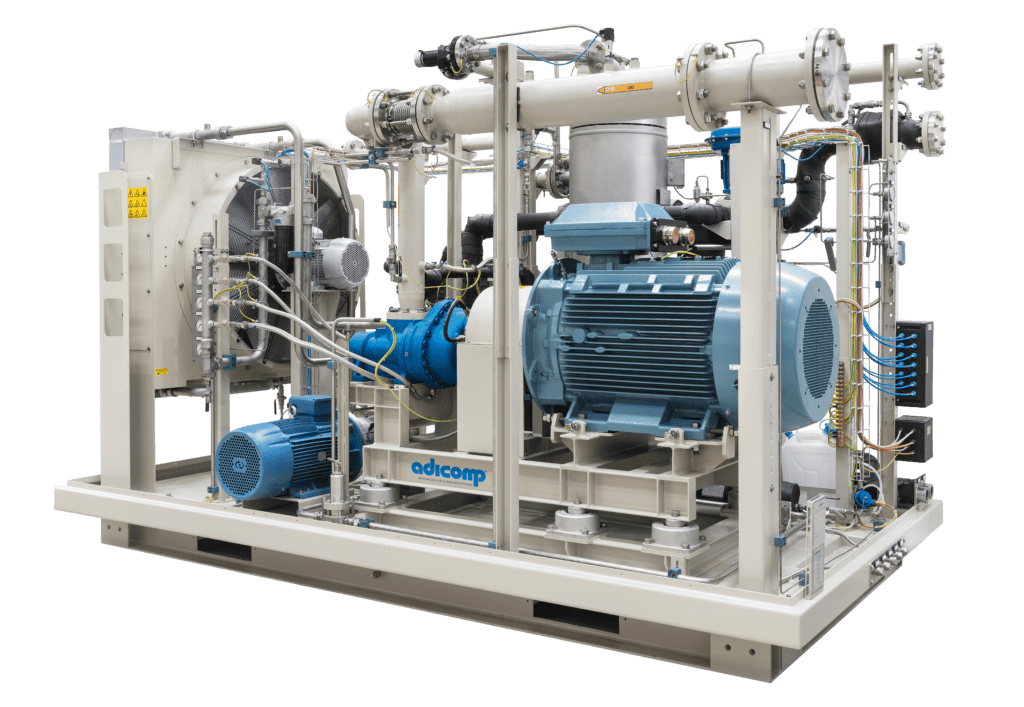

BVG/UVG series

These wet gas compression and treatment stations are designed into an easy handling skid composed of an oil-injected rotary gas screw block, directly coupled to an electric motor through a flexible or magnetic coupling inverter controlled.

Based on the application and on the operating pressure required, our compressors can be classified in:

• BVG: available operating pressures from 3.0 bar(g) to 10.0 bar(g).

• UVG: available operating pressures from 8.0 bar(g) to 25.0 bar(g).

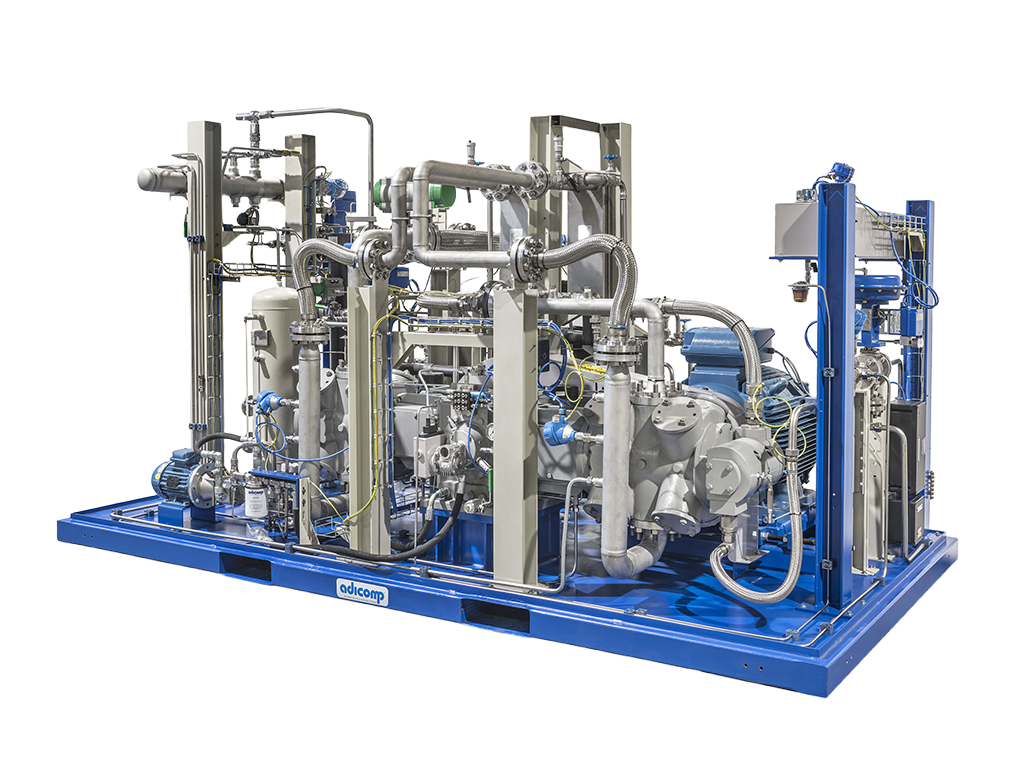

HOW IT WORKS

The wet gas is sucked through a suction filter acting also as a water separator with automatic condensate drain system, then the gas passes through a suction valve. All the components in contact with the gas are made in stainless steel or duly protected, due to the presence of H2S, CO2 and other aggressive contaminants into the gas. During the gas compression process, the oil is injected inside the rotary screw chamber to perform three main functions: lubrication, sealing and heat absorption. Working in a close circuit with a gas/oil receiver, oil is pressurized to flow through an oil cooler, then filtered before being injected again into the screw compression chamber.

The gas flows through the minimum pressure /no-return valve into a cooler and it is treated before leaving the package.