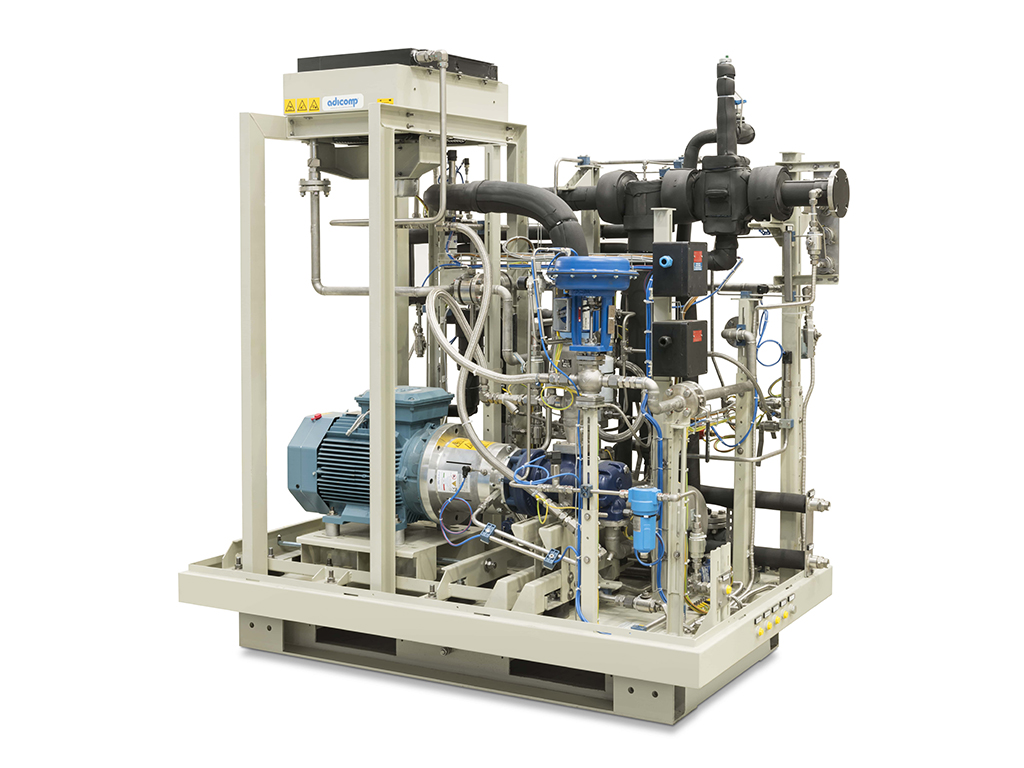

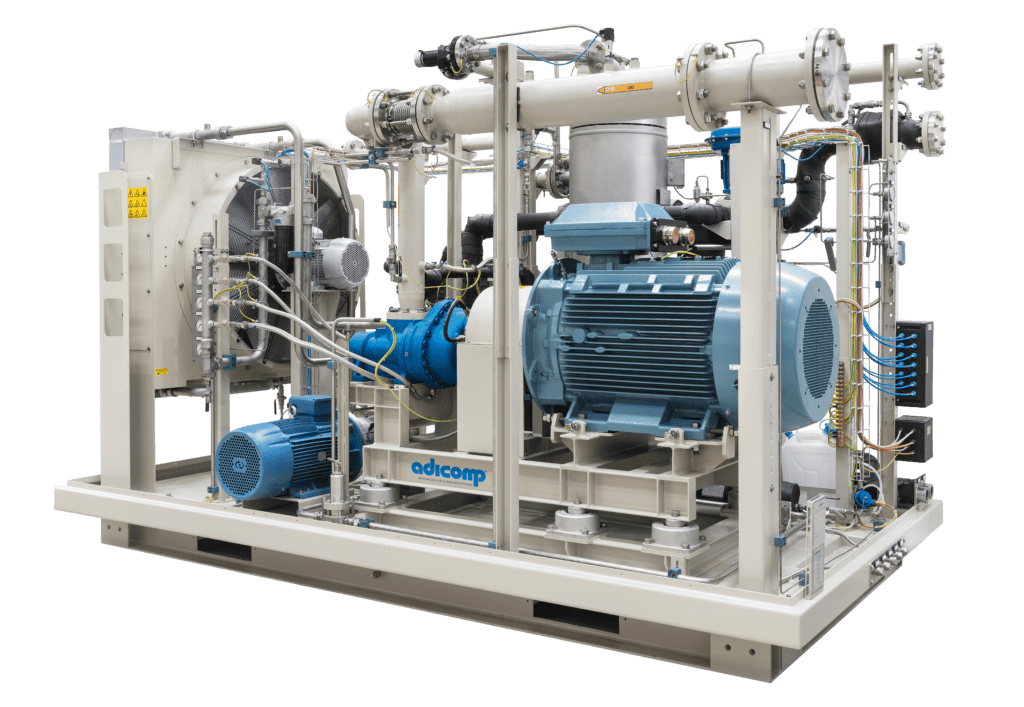

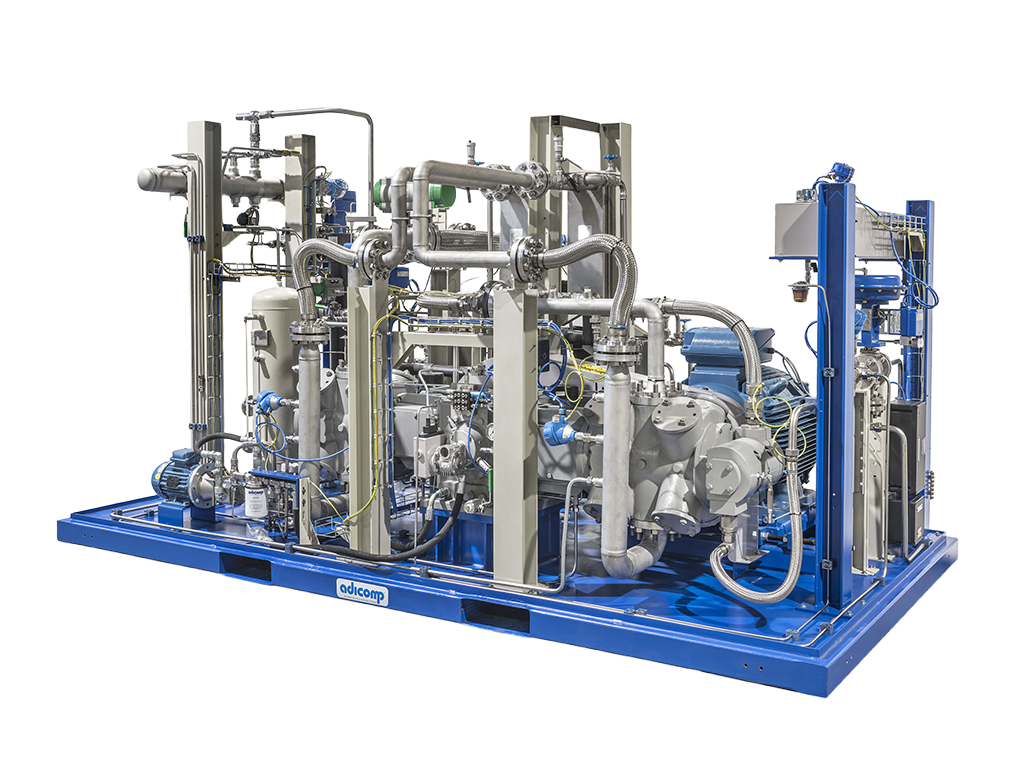

VG series

These dry gas compression and treatment stations are designed into an easy handling skid composed of an oil-injected rotary screw gas screw block, directly coupled to an electric motor through a flexible or magnetic coupling inverter controlled.

• VG: available operating pressures from 3.0 bar(g) to 25.0 bar(g).

HOW IT WORKS

The dry gas is sucked though a coarse type suction filter and then it passes through a suction control valve. During the gas compression process, oil is injected inside the rotary screw chamber to perform three main functions: lubrication, sealing and heat absorption.

The gas goes through the minimum pressure/non-return valve into an air or water cooler after cooler. A mechanical by-pass valve is used to recirculate the gas in excess into suction to reduce the capacity from the value achieved at minimum speed of the electric motor, down to 0%. Sometimes it is necessary to install a pneumatic or electric controlled by-pass valve to have a more accurate control. When the system stops, the gas is depressurized by feeding the gas into a specific expansion buffer or bleeding it out into the atmosphere.